所在地区: 广东-广东

发布时间:2014年05月18日

有 效 期:2014年05月31日

联 系 人:易敏

电 话:15800266623

Q Q:

联系地址:广东省深圳 宝安 公明

浏览次数:243

Easyand precise equipmentto welcome you,welcome to call15800266623 QQ826919878we will bethe best quality,the most perfectequipmentto return customers!

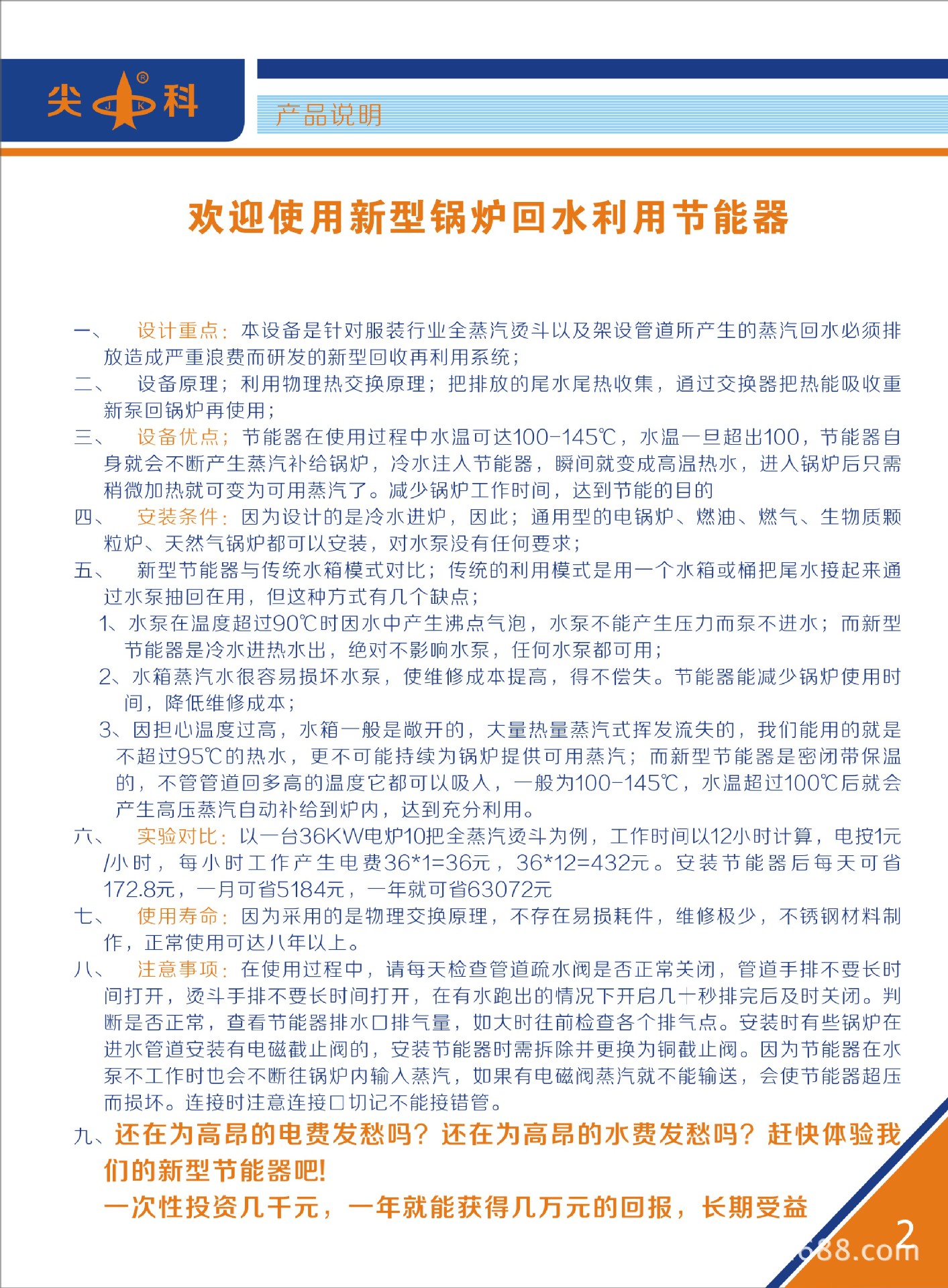

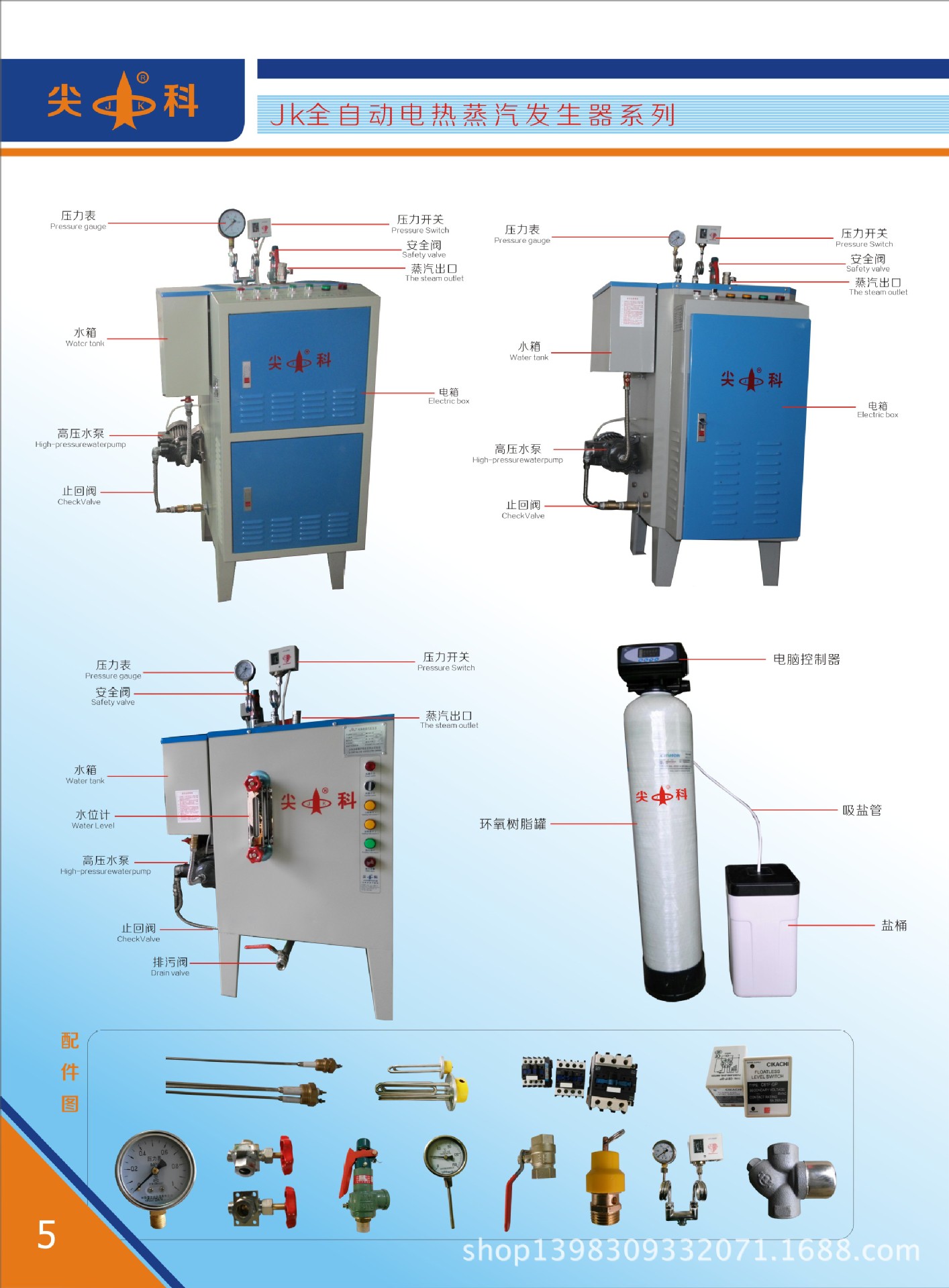

One, design focus; this equipment is new water steam backwater is produced in the apparel industry full steam iron and erection piping must be discharged causing serious waste and the development of recycling system.

Two, the principle of equipment; exchange principle using the physical heat, the heat of tail water tail exhaust collection, through the exchanger. The heat absorption re pump back to the boiler to use.

Three, the advantages of energy saving, equipment; water temperature can reach 100--145 degrees in the use process, the water once more than 100 degree energy saving device itself will continue to produce steam boiler feed water injection, energy saving device, suddenly became hot water into the boiler, after just a little heat into steam. Reduce boiler working time, achieve the purpose of energy saving.

Four, an oven is arranged; because the design is a cold water into the furnace, so the general type electric heating boiler, fuel, gas, natural gas, biomass pellet furnace, boiler can be installed, without any requirements on the pump.

Five, the new energy saving device with the traditional water tank model than the traditional mode of; use with a water tank or barrel. The tail water through the water pump to pump connected back to the boiler, but there are several drawbacks of this aspect; 1, pump more than 90 degrees when the boiling point of water to produce bubbles in the temperature, pressure and water pump can not produce the pump is not water and new energy-saving device is cold water into hot water, absolutely does not affect the water pump, water pump can be used in any 2, steam water tank is easy to damage the pump to improve, repair, The loss outweighs the gain., economizer can reduce boiler using time, reduce repair costs; 3, for fear of high temperature are generally open, a lot of the heat loss of steam volatile, can we have is not more than 95 degree water, less likely to continue to provide steam for the boiler, and the new energy-saving device is sealed with thermal insulation pipe back regardless of how high temperature it can be inhaled, usually 100---145 degrees, the water temperature exceeds 100 degrees will produce high pressure steam boiler can automatically recharge make full use of.

Six, experiments, using a 36KW boiler 10 all steam iron as an example, calculation of working hours to 12 hours, electricity 1 yuan per hour, every hour electricity 36 yuan by 12 hour is equal to 432 yuan, the installation of energy-saving device every day can save 172, 8 yuan in January to 5184 yuan, a year can save 63072 yuan.

Seven, the use of life; because of using the physical exchange principle, there is no easy loss, minimal repair, stainless steel material, the service life of up to 8 years.

Eight, is still high electricity worry, also for the high water and worry, to experience a new energy-saving device let 'one-time investment of several thousand dollars, a year can get several million yuan to return, the long-term benefit.

每项产品在出厂前公司多将通过严格的测试,产品内包含证书,说明书,合格证,等资料!节能器 有自己的专利证书,锅炉内胆是国内一流技术,安全可靠,锅炉成品是最新最节能的产品,我们一直以环保,节能,安全放在第一位!所以公司产品在一些领域上是有自己的领导地位的!请各位放心购买!

Each itemin the factorythe companythrough stricttest,the productcontainsinstructions,certificate,certificate,etc.data!Energy saving devicehas its own patent certificate,the boileris the domestic first-classtechnology,safe and reliable,the boileris finished inthe latestenergy-savingproducts,we have been toenvironmental protection,energy saving,safety first!So thecompany's products isour leadership positionin some fields!Please rest assured to buy!

用途:减少在缝制过程中,由于布料受缝制整烫所产生的收缩。

防止做出来的衣服产生尺寸变化或变形。

使布料裁剪得以顺利进行。

使轻布及布面间能精密的结合,经预缩机定型之布料,无需考量布料裁剪缝制 、整烫后的收缩,便于生产,又提高产 品之附加值。

特点:缩水加工是为了使未处理过之原布料柔软,并经过维纱斜度的调整,安定原布尺寸。

缩水加工后的原布尺寸,于缝制时不易产生布料缩皱而且易于缝制,使您在设计衣服及免除考虑在制作中所产生布料伸展及收缩的问题。

经缩水加工后的原布尺寸稳定,手感极佳,且经再次整烫也不易缩水,此种处理使产品的品质达到最佳,并且附加值得到增加。

此缩水机是现代使用CAD及CAM自动化设备必备的机器。

Purpose: to reduce in the sewing process, since the fabric by sewing ironing the contraction.

Keep the clothing's size changes or deformation.

The cloth cutting smoothly.

Combine light cloth and cloth to be precise, the shrinking cloth machine setting, without consideration of the cloth cutting and sewing, ironing shrinkage, easy production, and improve product added value.

Characteristics: the shrinkage processes in order to make the unprocessed raw soft cloth, and after the yarn inclination adjustment, the original fabric size stability.

Shrink the original cloth after processing dimensions, not easy to produce cloth for sewing shrinkage and easy to sew, enable you to design clothes and avoid considering produced cloth stretch and contract problems in production.

The original stable, cloth size shrink after processing the feel good, and once again the ironing is not easy to shrink, such that the quality of the products reach the best, and to increase the added value.

This machine is used by modern CAD and CAM automation equipment necessary machine.

1、内置精准红外线电子自对边系统,确保卷布布边整齐;

2、采用自动放布功能,使富弹性布置免受张力;

3、电子无级调速0~70m/min范围内任意调节;

4、卷布前可前后操作,方便检漏的布匹回卷重验。任意调节布匹张力或(无张力);

5、配置自动放布,送布按钮;

6、配置自动复位及自动停机功能;

7、有多种分色灯,以供对色;

8、采用进口透光材料,有强劲内外灯光使运行中的布料一览无遗;

9、采用电子记米器,可准确记录布匹数量,米数、码数自由切换。

10.配有折叠功能,可将检验完的布匹500-600mm宽幅折叠,特别对弹力大的布匹更能起到自然缩水功能。

Purpose: to reduce in the sewing process, since the fabric by sewing ironing the contraction.

Keep the clothing's size changes or deformation.

The cloth cutting smoothly.

Combine light cloth and cloth to be precise, the shrinking cloth machine setting, without consideration of the cloth cutting and sewing, ironing shrinkage, easy production, and improve product added value.

Characteristics: the shrinkage processes in order to make the unprocessed raw soft cloth, and after the yarn inclination adjustment, the original fabric size stability.

Shrink the original cloth after processing dimensions, not easy to produce cloth for sewing shrinkage and easy to sew, enable you to design clothes and avoid considering produced cloth stretch and contract problems in production.

The original stable, cloth size shrink after processing the feel good, and the

1, the built-in precision infrared electronic self to side system, ensure the cloth edge;

2, the automatic cloth function, from tension flexible layout;

3, the electronic stepless speed regulation 0~70m/min range of arbitrary regulation;

4, the cloth before the before and after the operation, easy to leak the re inspection cloth rollback. Any regulation or (cloth tension without tension);

5, configure automatic cloth, cloth feeding button;

6, configure automatic reset and automatic stop function;

7, there are a variety of color lamp, for the color;

8, using imported transparent material, strong internal and external lighting to make the cloth cover all at one glance in operation;

9, the electronic meter recording device, can accurately record the quantity of cloth, meters, code number free switch.

The 10 is equipped with a folding function, can be tested out cloth folding 500-600mm wide, especially more to natural shrinkage function of elastic large cloth.